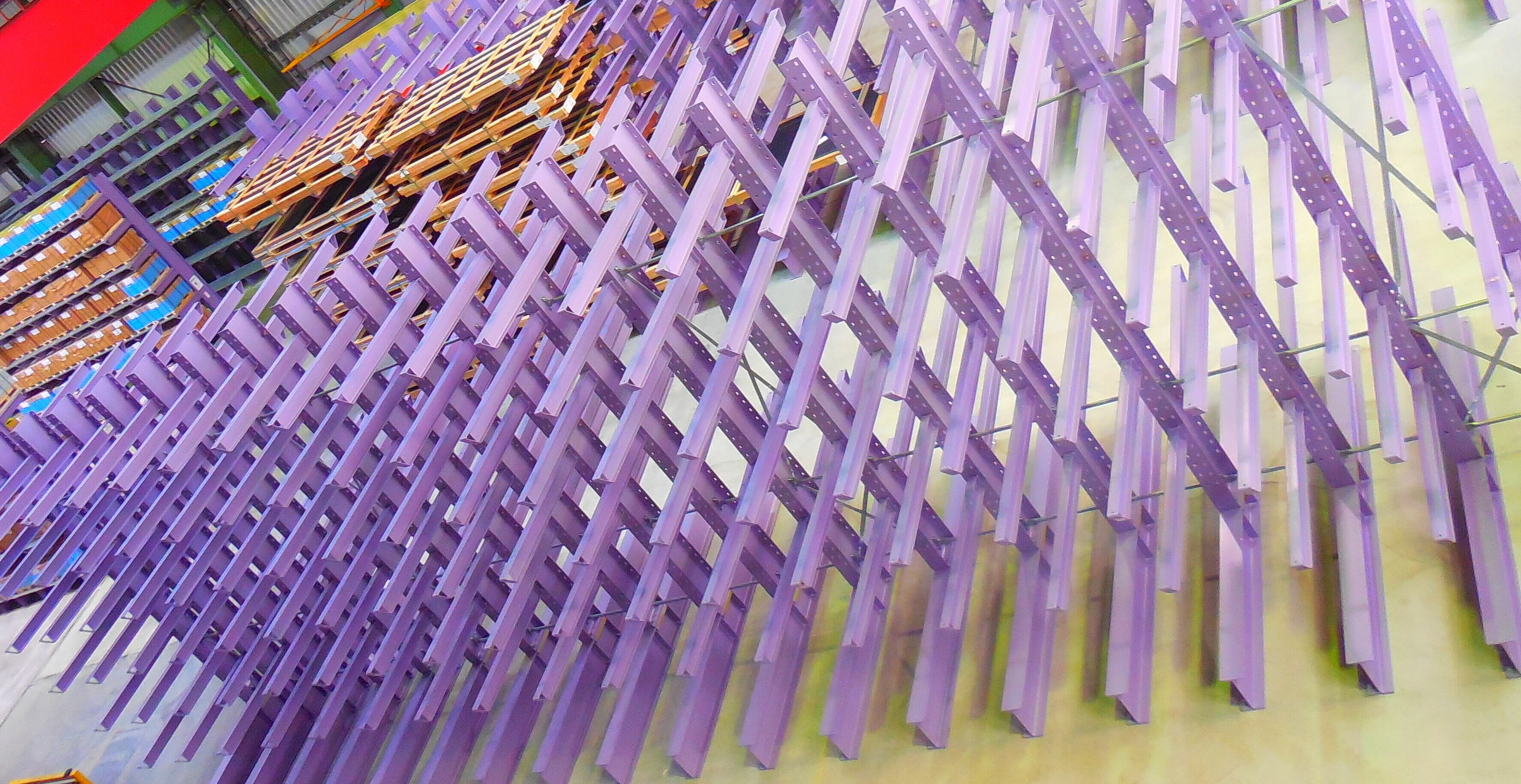

Conventional cantilever racks

Conventional cantilever racking is designed for the storage of long goods, bulky goods and heavy panels in warehouses and buildings. The stored goods are placed directly on the cantilever arms. Cantilever racking, consisting of vertical upright profiles and horizontally fixed upright feet and cantilever arms, has an enormous load-bearing capacity. Upright loads of up to 10,000 kg and arm loads of more than 2,000 kg are no problem due to the composition of hot-rolled steel profiles.

In which industries are conventional cantilever racks used?

Conventional cantilever racking is mainly found in production halls and warehouses. They are suitable for storing raw materials, semi-finished products or finished products in the picking and shipping warehouse. In almost all industries where storage is required, cantilever racking is the suitable storage system when it comes to storing particularly long, unwieldy or even heavy goods. For example, cantilever racking can be found in the timber, metal and building materials trade, in production plants and in joineries.

Features of conventional cantilever racking:

- Robust storage system for long goods and heavy loads

- One-sided and two-sided storage options

- No interfering intermediate supports

- Can be extended at any time

- Movable cantilever arms deflect when struck by the forks of a forklift truck

- Many accessories for individual storage equipment

Conventional Cantilever racks Gallery